垫圈. 交货技术条件 DIN 522 - 1990

-

尺寸公差

公差

产品等级

F

A

C

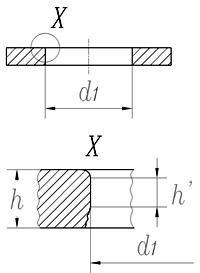

h

d1

h

d1

h

d1

≤4

H12

≤4

H13

≤4

H14

>4

H13

>4

H14

>4

H15

h

h′

minh

h′

minh

h′

min≤4

0.5h

≤4

0.5h

未定义

>4

0.3h

>4

0.3h

公差

产品等级

F

A

C

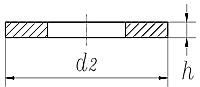

h

d2

h

d2

h

d2

≤4

h13

≤4

h14

≤4

h16

>4

h14

>4

h15

>4

h16

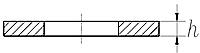

公差

产品等级

F

A

C

h

极限

偏差h

极限

偏差h

极限

偏差≤0.5

±0.04

≤0.5

±0.05

/

/

>05≤1

±0.06

>05≤1

±0.1

≤1

±0.2

>1≤2.5

±0.12

>1≤2.5

±0.2

>1≤2.5

±0.3

>2.5≤4

±0.16

>2.5≤4

±0.3

>2.5≤4

±0.6

>4≤6

±0.2

>4≤6

±0.6

>4≤6

±1

>6≤10

±0.24

>6≤10

±1

>6≤10

±1.2

>10≤20

±0.28

>10≤20

±1.2

>10≤20

±1.2

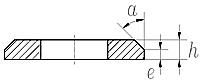

公差

产品等级

F

A

C

α=30°~ 45°

emin = 0.25h

emax = 0.5h未定义

-

几何公差

公差

产品等级

F

A

C

h

Δh

h

Δh

h

Δh

≤0.5

0.02

≤0.5

0.025

未定义

>0.5≤1

0.03

>0.5≤1

0.05

>1≤2.5

0.06

>1≤2.5

0.1

>2.5≤4

0.08

>2.5≤4

0.15

>4≤6

0.1

>4≤6

0.2

>6≤10

0.12

>6≤10

0.3

>10≤20

0.14

>10≤20

0.4

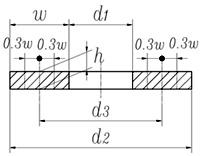

Δh的要求仅适用于d2-0.3w和d3+0.3w定义的区域。

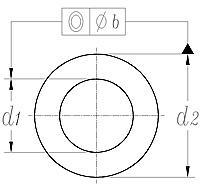

公差

产品等级

F

A

C

d2

b

d2

b

d2

b

≤50

2IT11

≤50

2IT12

≤50

2IT15

>50

2IT12

>50

2IT13

>50

2IT16

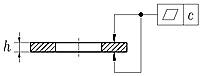

公差

产品等级

F

A

C

h

c①

h

c①

h

c

≤0.5

0.07

≤0.5

0.1

未定义

>0.5≤1

0.1

>0.5≤1

0.15

>1≤2.5

0.2

>1≤2.5

0.2

>2.5≤4

0.3

>2.5≤4

0.3

>4≤6

0.4

>4≤6

0.4

>6≤10

0.6

>6≤10

0.6

>10≤20

1

>10≤20

1

①对于不锈钢制成的垫圈,最大允许平面度公差应等于2c。

-

基本公差和公差带

基本尺寸

基本公差

公差带

外部尺寸

内部尺寸

Over

Up to

IT11

IT12

IT13

IT14

IT15

IT16

IT13

IT14

IT15

IT16

IT12

IT13

IT14

IT15

-

3

0.06

0.10

0.14

0.25

0.40

0.60

0, -0.14

0, -0.25

0, -0.40

0, -0.60

+0.10, 0

+0.14, 0

+0.25, 0

+0.40, 0

3

6

0.075

0.12

0.18

0.30

0.48

0.75

0, -0.18

0, -0.30

0, -0.48

0, -0.75

+0.12, 0

+0.18, 0

+0.30, 0

+0.48, 0

6

10

0.09

0.15

0.22

0.36

0.58

0.90

0, -0.22

0, -0.36

0, -0.58

0, -0.90

+0.15, 0

+0.22, 0

+0.36, 0

+0.58, 0

10

18

0.11

0.18

0.27

0.43

0.70

1.10

0, -0.27

0, -0.43

0, -0.70

0, -1.10

+0.18, 0

+0.27, 0

+0.43, 0

+0.70, 0

18

30

0.13

0.21

0.33

0.52

0.84

1.30

0, -0.33

0, -0.52

0, -0.84

0, -1.30

+0.21, 0

+0.33, 0

+0.52, 0

+0.84, 0

30

50

0.16

0.25

0.39

0.62

1.00

1.60

0, -0.39

0, -0.62

0, -1.00

0, -1.60

+0.25, 0

+0.39, 0

+0.62, 0

+1.00, 0

50

80

0.19

0.30

0.46

0.74

1.20

1.90

0, -0.46

0, -0.74

0, -1.20

0, -1.90

+0.30, 0

+0.46, 0

+0.74, 0

+1.20, 0

80

120

0.22

0.35

0.54

0.87

1.40

2.20

0, -0.54

0, -0.87

0, -1.40

0, -2.20

+0.35, 0

+0.54, 0

+0.87, 0

+1.40, 0

120

180

0.25

0.40

0.63

1.00

1.60

2.50

0, -0.63

0, -1.00

0, -1.60

0, -2.50

+0.40, 0

+0.63, 0

+1.00, 0

+1.60, 0

180

250

0.29

0.46

0.72

1.15

1.85

2.90

0, -0.72

0, -1.15

0, -1.85

0, -2.90

+0.46, 0

+0.72, 0

+1.15, 0

+1.85, 0

适用范围

This standard specifies requirements for metal washers manufactured by stamping (punching) which thus exhibit inside and outside rollover and fracture (cf. DIN 6930 Part 2 and DIN 6932). it does not cover washers manufactured by machining (e.g. by drilling or turning).

本标准规定了垫圈的公差和极限偏差,垫圈的首选应用是螺栓/螺母组件。这些公差将用于处理F、A和C级产品垫圈的标准,这些垫圈专为公称螺纹直径为1~160mm的螺栓、螺钉和螺母设计。